Brand: TSM

Material: Nickel, Nickel Alloy

Size :M2-M30 or Customized

Length: 3 mm to 200 mm or customized

Surface Finish: Electropolishing, Shot Peening, PTFE Coating

Standards: IS / BS / ASTM

Delivery time: 10-25 days

Payment terms: T/T, L/C, Paypal, West Union or as required

inquiry now

TSM TECHNOLOGY CO., LTD. is a leader in AS 9120 certified aerospace grade fastening solutions. Our nickel washers are engineered to meet the stringent requirements of NASA, ESA and defense contractors. TSM has focused on manufacturing nickel washers for 14 years.

What are nickel washers?

Nickel washers are precision gaskets made from nickel alloys (e.g., Nickel 200, Inconel 625, Monel 400, etc.) Nickel alloy washers are renowned for their superior corrosion resistance, maintaining excellent performance even in highly corrosive environments such as seawater and chemical processing plants. Their durability ensures long-term reliable performance, reducing the need for frequent replacement. In addition, their excellent weldability enables seamless integration into complex assemblies, making them an indispensable material in critical applications ranging from offshore platforms to chemical reactors.

Characteristics of Nickel

High Melting Point, 1453 degrees C

Resists corrosion and oxidation

Magnetic at room temperature

Can be deposited by electroplating

Has catalytic properties

Nickel Washer Specifications

1. Material Grade: Nickel 200/201, Inconel 600/601/625/718, Hastelloy C276/C22/B3, Monel 400/K500, Incoloy 800/825, etc.

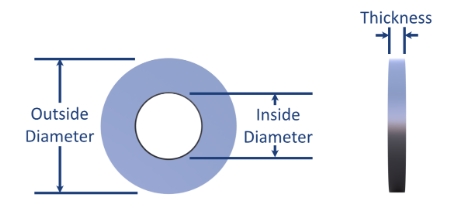

2.Size Range: 2mm–100mm ID, 5mm–150mm OD

3. Thickness: 0.1mm–10mm (±0.002mm tolerance)

4 .Surface Finish: Electropolishing, Shot Peening, PTFE Coating

Types of Nickel Washers

Flat Washer

Spring Washer

Square Washer

Belleville Washer

Dock Washer

Fender Washer

Lock Washer

Split Washer

Star Washer Springs

Machine Washer

Flat Spring & Wire Spring

Custom Washers: Customized design and size customization according to your needs to meet special engineering requirements

Key Benefits

🔹5x longer service life than stainless steel washers in corrosive environments.

🔹Non-magnetic properties for MRI and semiconductor devices.

🔹Customizable thickness (0.1mm to 10mm) and inner/outer diameters.

Nickel Washer Applications

✔Aerospace: Applicable to aircraft structures, engine components and other critical connections.

✔Oil and Gas: Prevent fasteners from loosening or being damaged in subsea flange and pipeline connections.

✔Marine Engineering: In the fastening of equipment resistant to seawater corrosion, ensuring equipment reliability in harsh environments.

✔Automobile Manufacturing: Used in automobile chassis, engines and transmission systems to ensure long-term stability.

Our Services

End-to-End Fastener Solutions

Customized Processing: Laser cut or stamped washers with an accuracy of ±0.002mm.

Material Certification: Mill Test Report (MTR) with traceable heat number.

Coating Services: Chemical nickel plating, PVD coating for improved wear resistance.

Kitting and Packaging: Provide pre-assembled washers/bolt sets for OEMs.

Contact us

For more details on Nickel Washers or to obtain a quote, please contact TSM TECHNOLOGY CO., LTD at: info@tsmfasteners.com. We look forward to working with you to provide high-quality fastener solutions for your project.

Keywords: Nickel Washers, Nickel fasteners,Nickel alloy fasteners,Nickel 200 Washers,Nickel spring washer, Nickel Punched Washer, Nickel Flat Spring Manufacturer, Nickel Flat Washers, Nickel Lock Washers, Nickel Machine Washers ,Nickel Alloy Washers

TSM factory and Processing equipment

Certificate