Brand: TSM Technology

Material: Titanium, Nickel, Copper, Aluminum

3 factories*8 production lines*70+ machines

Supply Ability: 300,000 PCS

Size :M2.5-M64 or Customized

Length: 1mm-1990 mm or customized

Standards: ASTM, DIN, JIS, BS, GB/T

MOQ:100PCS

Provide Free sample

inquiry now

TSM Technology is a trusted manufacturer and global supplier of high-performance Titanium Hex Bolts, designed for critical applications requiring superior strength, corrosion resistance, and low weight. Our titanium hex bolts are manufactured from premium-grade titanium alloys such as Grade 2 (commercial pure) and Grade 5 (Ti-6Al-4V). They offer outstanding strength-to-weight ratio, corrosion resistance, and biocompatibility, making them ideal for critical industrial, medical, and performance applications.

| Grade | Composition | Properties | Typical Applications |

|---|---|---|---|

| Grade 2 (Gr2) | Commercially pure titanium | Excellent corrosion resistance and formability | Marine, chemical applications |

| Grade 5 (Ti-6Al-4V, Gr5) | 6% Aluminum, 4% Vanadium | High-strength alloy with excellent mechanical properties | Aerospace, motorsports |

| Grade 7 (Gr7) | Pure titanium with palladium | Enhanced corrosion resistance in reducing/oxidizing environments | Chemical processing |

DIN 933

ISO 4017

ANSI/ASME B18.2.1

ASTM B348

Metric (M3–M30)

UNC/UNF upon request

Polished

Anodized (multiple colors)

Passivated

Custom finishes available

| Feature | Benefit |

|---|---|

| Exceptional strength-to-weight ratio | Up to 45% lighter than steel with comparable strength |

| Corrosion resistance | Excellent resistance to saltwater, acids, and industrial chemicals |

| Lightweight | Density only 60% of steel |

| Non-magnetic | Suitable for precision equipment like MRI machines |

| Biocompatibility | Non-toxic and suitable for medical applications |

Aircraft components where weight and strength are critical

High-performance vehicles and racing cars for reduced weight

Seawater-exposed applications like ships and offshore platforms

Surgical instruments and implantable devices

Environments with exposure to corrosive substances

| Test Process | Purpose | Standard |

|---|---|---|

| Spectrometer | Material composition verification | ASTM E1251 |

| Metallographic testing | Grain size control | ASTM E112 |

| Heat treatment traceability | Process parameters verification | AMS-H-81200 |

| Universal testing machine | Mechanical properties test | ASTM E8 |

| Hydrogen content detection | Prevent hydrogen embrittlement (≤150ppm) | ASTM F1440 |

| Thread inspection | Full inspection with go/no-go gauges | ASME B1.2 |

| Surface defect detection | Industrial endoscope inspection | ASTM E1444 |

Certification: EN 10204 3.1 material certificate provided for each batch

Free selection guidance

Sample provision

Non-standard thread design (UNC/UNF/UNEF)

Custom surface treatment (anodizing/sandblasting passivation)

Vacuum anti-sticking packaging

Third-party testing services

| Question | Answer |

|---|---|

| What is the minimum order quantity? | Standard products: 100 pieces minimum Customized parts: 500 pieces minimum |

| Do you accept customized drawings? | Yes, we support STEP/IGES format drawings and provide DFM analysis reports within 3 days |

| How long is the delivery cycle? | Standard parts: 15-25 working days Custom parts: 25-35 working days |

Contact us

For more details on Titanium hex bolts or to obtain a quote, please contact TSM TECHNOLOGY CO., LTD at: info@tsmfasteners.com. We look forward to working with you to provide high-quality fastener solutions for your project.

TSM factory and Processing equipment

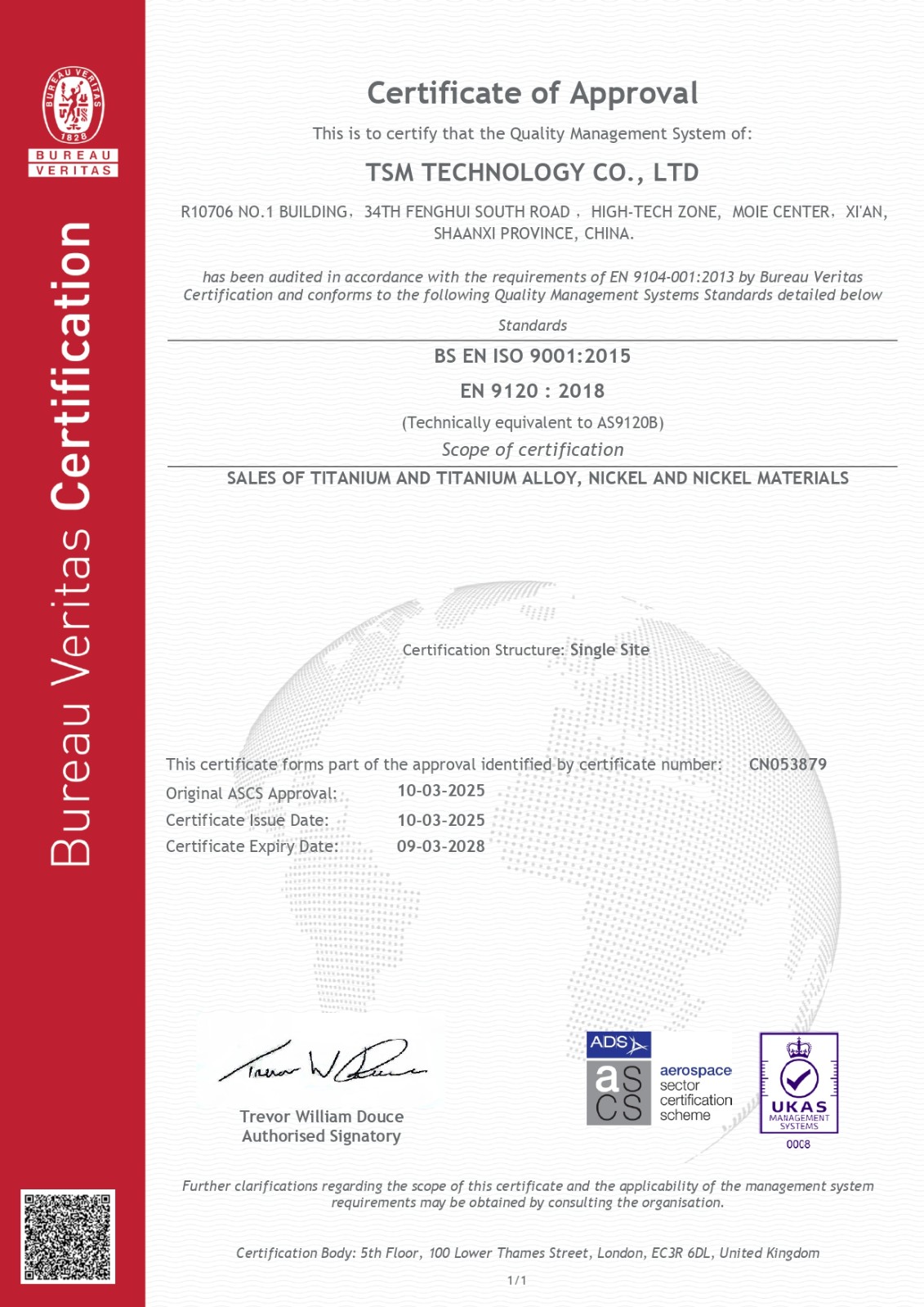

Certificate