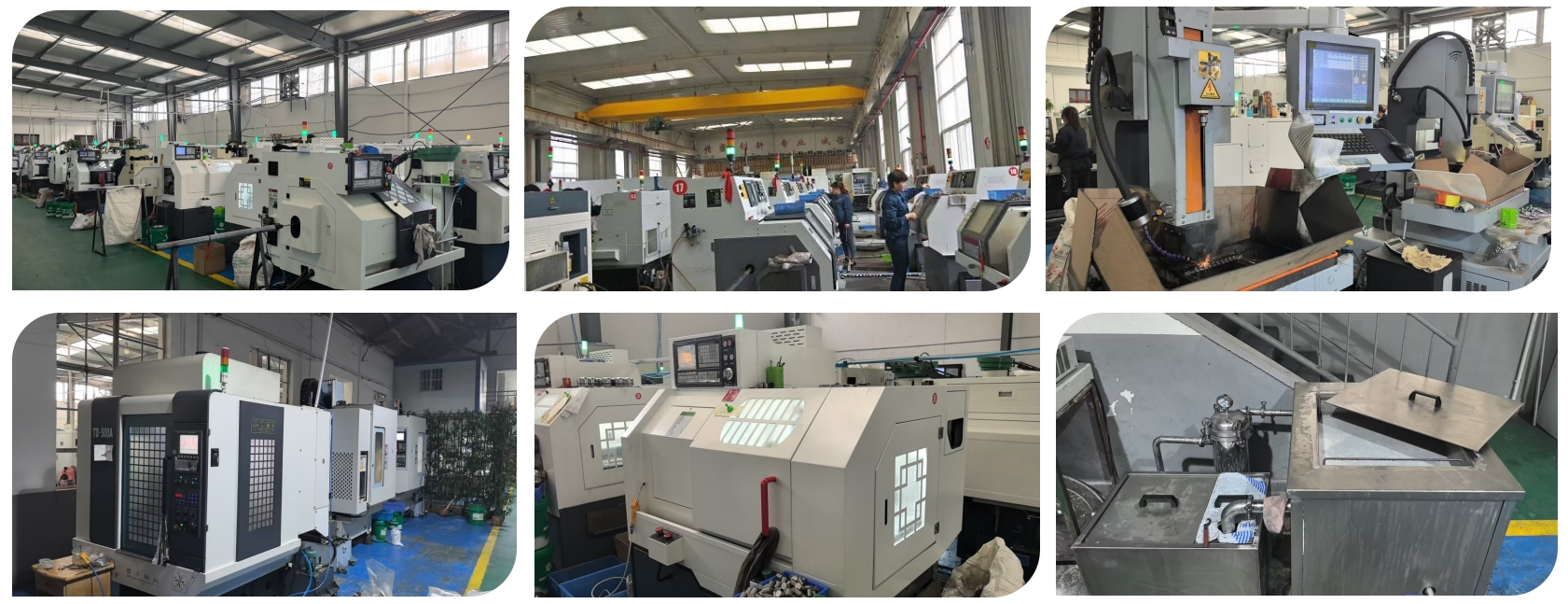

3 factories*8 production lines*100+ machines

Supply Ability:100,000 -300,000 PCS

Grades: 6061/7075 Aluminum

Types: Hex Nuts, Nylock Nuts, Wing Nuts

Standards: ISO 4032, DIN 934

Size: M2.5-M32 or Customized

Finish: Plain, Anodized

Delivery time: Usually about 10-25 days

Provide Free sample

inquiry now

Aluminum Nuts | High-Precision Aluminum Alloy Fastener Manufacturer — TSM TECHNOLOGY

Aluminum nuts, due to their lightweight, corrosion-resistant, and high-strength properties, are an ideal choice for industries such as aerospace, new energy vehicles, and electronic equipment. As a leading aluminum nut manufacturer in China, TSM TECHNOLOGY specializes in precision machining of 6061 and 7075 aluminum alloys, providing cost-effective, customized fastener solutions to help customers reduce procurement costs and improve assembly efficiency.

Specification

| Material | 6061-T6 / 7075-T6 Aluminum Alloy |

| Size Range | M3-M24 (Standard) |

| Custom Options | Diameter, Thickness, Thread Type (Metric/UNC/UNF) |

| Surface Finish | Anodizing (Color Options), Passivation, Sandblasting, Electroplating |

| Mechanical Properties | Tensile Strength: 310-572 MPa (Depending on Alloy) |

| Certifications | ISO 9001, ASTM F594, RoHS Compliant |

| MOQ | 500 pieces (Standard Items) |

Global Applications of TSM Aluminum Nuts

✔New Energy Vehicles: Reliable connection between lightweight battery packs and motor frames.

✔Aerospace: High-temperature fastening for satellite mounts and drone structures.

✔Industrial Automation: Vibration-resistant design for robotic joints and conveyor systems.

✔Consumer Electronics: Anti-corrosion solutions for PCB board mounting and heat sink assembly.

Quality Inspection

Key Features

6061-T6: Good strength, excellent corrosion resistance

7075-T6: High strength (comparable to steel), aerospace-grade

All finishes meet MIL-A-8625 and ASTM B580 standards

Full material certification and test reports available

TSM factory and Processing equipment

Why Choose TSM Aluminum Nuts?

1. Excellent Material Properties

6061 Aluminum Alloy: Suitable for general industrial applications, it offers excellent corrosion resistance and weldability, and is widely used in automotive parts, consumer electronics, and building structures.

7075 aerospace-grade alloy: Provides ultra-high strength (tensile strength ≥ 500 MPa) and fatigue resistance, meeting the extreme environmental demands of UAVs and satellite components.

Strict Certifications: All products comply with ISO 9001, RoHS, and ASTM standards, and third-party test reports are provided.

2. Precision Manufacturing

Utilizing CNC lathes and cold heading technology, tolerances as high as ±0.05mm are achieved, ensuring a precise thread fit.

A variety of surface finishes are available: anodizing (available in black, silver, or color), passivation, or sandblasting for enhanced wear resistance and aesthetics.

3. Flexible Supply Models

Fast Delivery: Standard parts are in stock, with global shipping time of 15 days; custom orders take just 10-20 days.

Transparent Pricing: We offer tiered pricing (minimum order quantity 500 pieces) and a 12% discount on bulk orders, eliminating any middleman markups.

FAQ

Q: How do I choose between 6061 and 7075 aluminum nuts?

A: 6061 is suitable for general industrial environments, while 7075 is used in high-stress applications (such as aerospace fastening).

Q: Are there additional charges for custom aluminum nuts?

A: For orders over 50,000 pieces, we offer free tooling fees and 3D model verification services.

Q: How reliable are Chinese suppliers?

A: TSM offers a 15-day delivery guarantee and a 0.1% delay allowance based on the contract date.

Contact us now for a free consultation!

Whether you are looking for a reliable supplier or manufacturer of Aluminum Nuts at competitive prices, TSM TECHNOLOGY in China has you covered. Contact us at: info@tsmfasteners.com