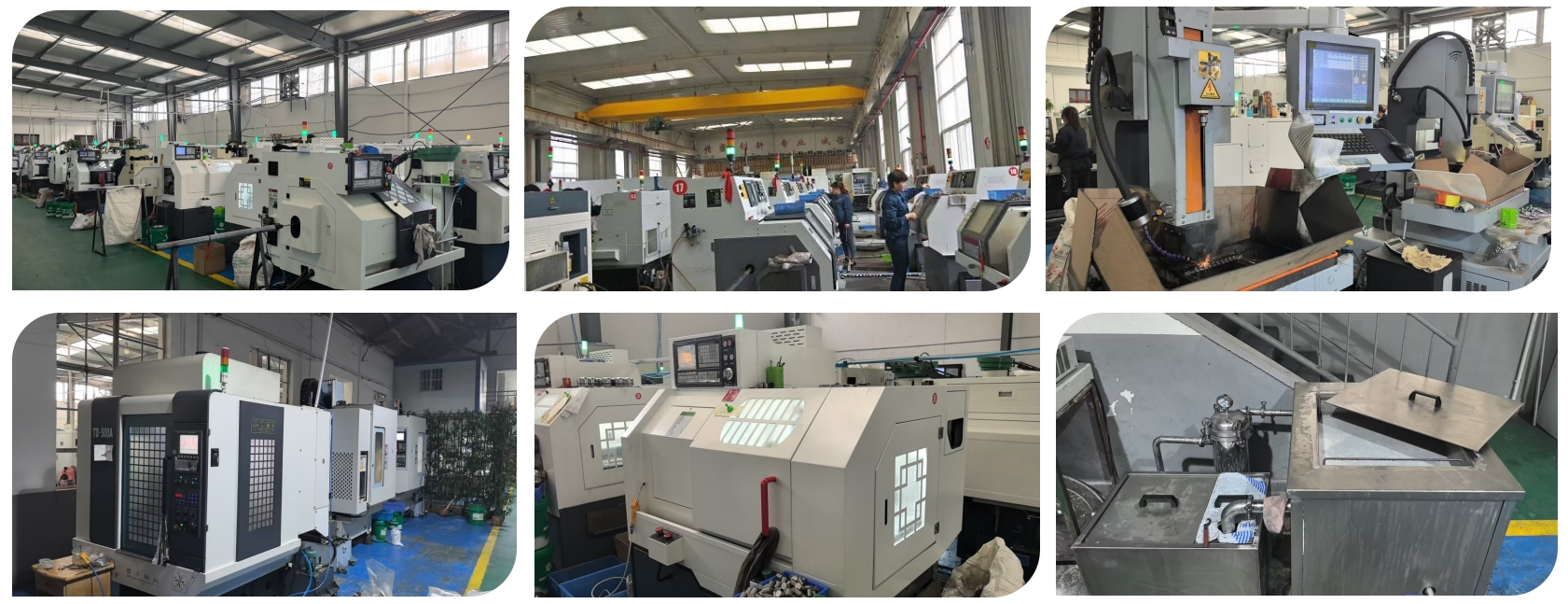

3 factories*8 production lines*100+ machines

Supply Ability:100,000 -300,000 PCS

Material: 6061-T6 Aluminum

Drive Types: Hex Socket, Flat Head

Points: Cup, Flat, Oval

Standards: DIN 916, ISO 4026

Size Range: M3-M12

Delivery time: Usually about 10-25 days

Provide Free sample

inquiry now

TSM TECHNOLOGY, a professional aluminum set screw manufacturer and supplier, specializes in the production and export of set screws in various aluminum alloys, including 6061 and 7075. Our high-quality manufacturing process, strict quality control, and competitive pricing have made us the preferred choice for aluminum set screws in China. Whether you're purchasing in bulk or ordering small samples, TSM provides prompt response and comprehensive service to ensure your project goes smoothly.

What are aluminum set screws?

Aluminum set screws, also known as aluminum headless set screws, are used for positioning, clamping, or preventing relative motion between parts. Common point configurations include flat point, cup point, cone point, and half-dog point, meeting the torque and corrosion resistance requirements of various industries. Compared to steel set screws, aluminum set screws offer advantages such as lighter weight and greater corrosion resistance, making them particularly suitable for applications in aerospace, electronics, and precision instrumentation.

Material and Specifications

1.6061 Aluminum Alloy: Excellent corrosion resistance and processability, commonly used for positioning and tightening electronic housings and light-load structures.

2.7075 Aluminum Alloy: High strength and fatigue resistance, suitable for heavy-load applications (such as positioning aviation components).

Point Types: Flat, cup, conical, half-dog, and nylon points are available.

Drive Types: Hexagon socket and slotted are the two most common types.

Advantages

✔ Lightweight: Aluminum's density is only one-third that of steel, effectively reducing the overall weight.

✔ Corrosion Resistance: A natural oxide film enhances oxidation resistance, making it suitable for outdoor and marine environments.

✔ Cost Advantage: Thanks to localized production and supply chain integration in China, prices are more competitive.

✔ Diverse Supplier Partnerships: TSM Technology offers customized packaging, whether palletized or bulk, to quickly meet large-volume orders.

Specification

| Parameter | Description |

|---|---|

| Material | Aluminum Alloy 6061, 7075 |

| Standards | ASME B18.3 / DIN 913, 914, 915, 916 |

| Size Range | M3–M48 (custom sizes available) |

| Surface Finish | Anodizing, Nickel Plating, Coloring |

| Minimum Order Quantity | 500 PCS |

Quality Inspection

Applications

Aerospace: High-strength 7075 aluminum set screws are commonly used for clamping and positioning aircraft avionics equipment.

Electronics and Communications: 6061 screws are used for circuit board support, chassis fixing, and electromagnetic interference resistance.

Mechanical Equipment: Used for positioning and locking precision instruments and robotic joints.

Automotive: Lightweight positioning fasteners reduce vehicle weight and improve fuel economy.

TSM factory and Processing equipment

Why Choose TSM TECHNOLOGY?

🔹Direct from the Manufacturer: Eliminate intermediaries, manage costs, and achieve competitive pricing.

🔹Quality Assurance: ISO 9001 certification and multiple inspection processes ensure every set screw meets standards.

🔹Flexible Delivery: Regular stock and custom production options are available to meet both urgent and bulk orders.

🔹Made in China: A comprehensive aluminum alloy raw material supply chain and sophisticated processing equipment enable rapid response to global customers.

🔹Comprehensive Service: From consultation and sampling to mass production, we offer one-stop procurement solutions to help customers reduce costs and increase efficiency.

Contact us

For more information, quotes, or samples on our Aluminum Set Screws, please contact us at: info@tsmfasteners.com