3 factories*8 production lines*100+ machines

Supply Ability:100,000 -300,000 PCS

Material: 6061/7075 Aluminum Alloy

Thread: Metric/UNC

Head Types: Pan, Flat, Oval

Drive: Phillips/Slot/Hex

Size: M2-M12

Standards: ISO 1207, DIN 7985

Delivery time: Usually about 10-25 days

Provide Free sample

inquiry now

What Are Aluminum Machine Screws?

Aluminum machine screws are precision-engineered fasteners designed for applications requiring lightweight, corrosion resistance, and durability. Made from 6061 and 7075 aluminum alloys, these screws combine high tensile strength with excellent thermal and electrical conductivity, making them ideal for aerospace, automotive, electronics, and industrial machinery.

Technical Specifications

Parameter | 6061 Aluminum Screws | 7075 Aluminum Screws |

Tensile Strength | 205–310 MPa | 510–570 MPa |

Yield Strength | 110–276 MPa | 430–505 MPa |

Corrosion Resistance | High (anodized) | Moderate (requires coating) |

Temperature Range | -50°C to 150°C | -50°C to 120°C |

Data complies with GB/T 3880-2006 and ASTM B221 standards.

Applications of Aluminum Machine Screws

Aerospace: Engine mounts, fuselage panels.

Automotive: EV battery frames, chassis components.

Electronics: Heat sinks, PCB mounting.

Renewable Energy: Solar panel brackets, wind turbine assemblies.

Quality Control Tests for Aluminum Machine Screws

Test Category | Test Method | Standard / Requirement | Result/Value |

Dimensional Inspection | Thread verificatio (Go/No-Go gauges) | ISO 2768-m tolerance | Compliant |

Head height & drive socket depth measurement | ISO 4762 | ±0.01mm accuracy | |

Mechanical Properties | Tensile Strength | Alloy-dependent (6061/7075) | 310-572 MPa |

Hardness (Brinell) | 75-95 HB | 78-92 HB | |

Torque-to-Failure Analysis | Industry standards | Meets specifications | |

Corrosion Resistance | Salt Spray Testing (ASTM B117) | 500+ hours without red rust | 600+ hours |

Cyclic Environmental Exposure | Humidity/temperature cycling | No corrosion observed | |

Surface Quality | Coating thickness (anodizing) | 10-25μm | Compliant |

Adhesion testing (cross-cut tape method) | No peeling | 0% failure | |

Visual inspection | No defects (cracks, burrs, etc.) | Pass | |

Chemical Composition | Spectrometry analysis | 6061/7075 alloy standards | Compliant |

RoHS Compliance | Directive 2011/65/EU | C |

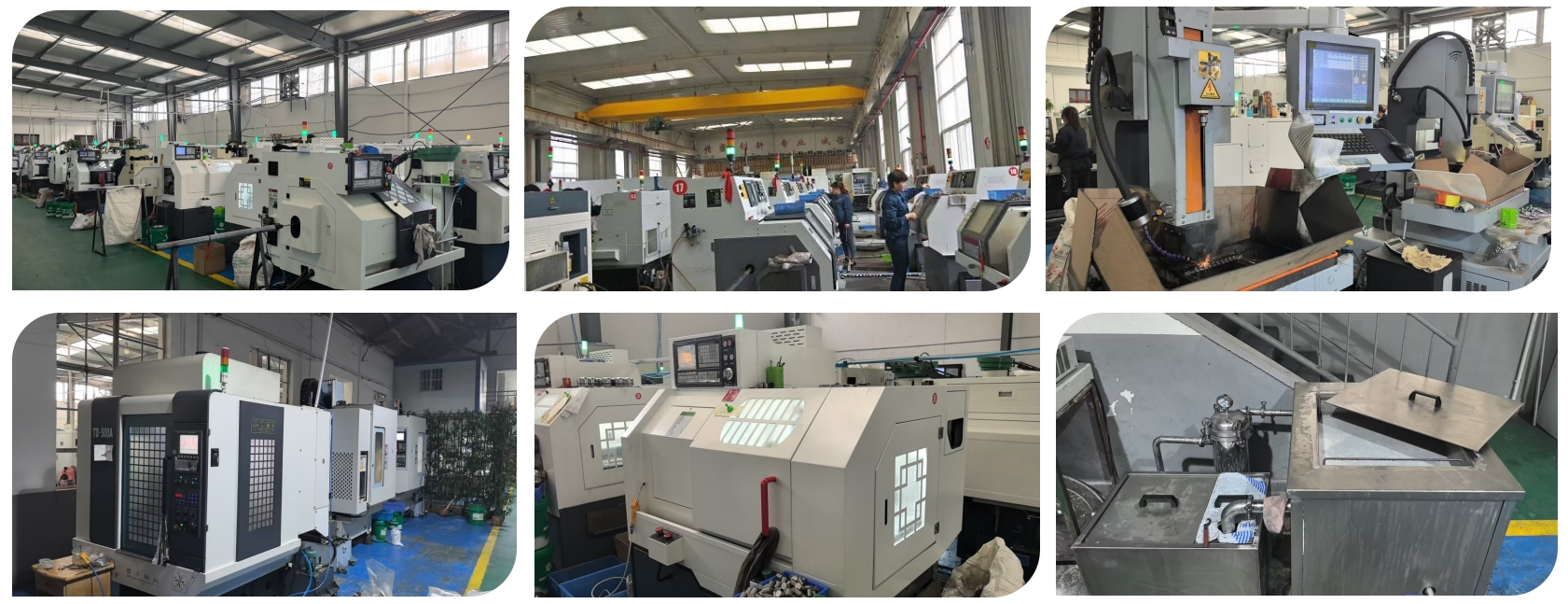

TSM factory and Processing equipment

Why Choose TSM TECHNOLOGY?

1. Premium Materials for Superior Performance

6061 Aluminum: Offers excellent weldability and machinability with a tensile strength of ≥205 MPa, ideal for general-purpose industrial use.

7075 Aluminum: Aerospace-grade alloy with a tensile strength of ≥570 MPa, perfect for high-stress environments like aviation and defense.

Custom Alloys: Optional 2024 or 5052 aluminum for specialized requirements.

2. Precision Manufacturing & Strict Quality Control

As a leading aluminum machine screws manufacturer and supplier in China, TSM TECHNOLOGY ensures:

ISO 9001 Certified: Compliant with global automotive and industrial standards.

Advanced CNC Machining: Tight tolerances (±0.01 mm) and thread consistency for seamless integration.

Third-Party Testing: Salt spray tests (ASTM B117) and load capacity reports available upon request.

3. Cost-Effective Solutions for Global Procurement

Competitive Pricing: Optimized production scales reduce costs without compromising quality.

MOQ Flexibility: Order from 1,000 units for prototypes to bulk quantities (10,000+ units).

Fast Lead Times: 15-day standard delivery, expedited options available.

Contact us

Whether you are looking for a reliable supplier or manufacturer of Aluminum machine screws at competitive prices, TSM TECHNOLOGY in China has you covered. Contact us at: info@tsmfasteners.com