3 factories*8 production lines*100+ machines

Supply Ability:100,000 -300,000 PCS

Materials: 6061/7075 Aluminum Alloy

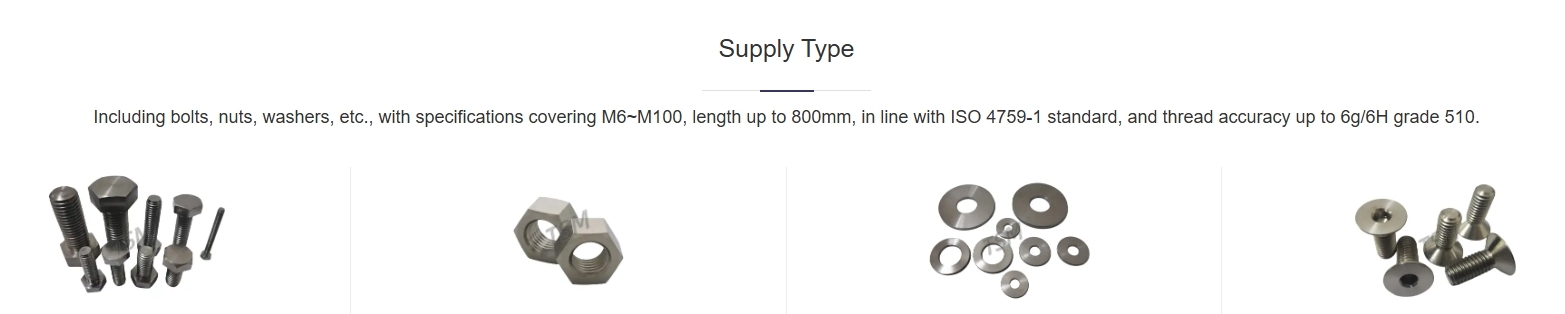

Product Range: Bolts, Nuts, Screws, Washers

Standards: ISO, DIN, ASTM, JIS

Finish Options: Natural, Anodized, PTFE Coated

Features: 1/3 Weight of Steel, Non-Sparking

Delivery time: Usually about 10-25 days

Provide Free sample

inquiry now

TSM TECHNOLOGY is a leading fastener manufacturer with over 14 years of industry expertise. Our 3,200㎡ advanced production facility features state-of-the-art equipment including 5-axis machining centers, CNC lathes, and thread rolling machines, enabling us to deliver precision aluminum fasteners from M1 to M64 sizes. Specializing in high-strength aluminum alloys, we provide lightweight, corrosion-resistant solutions for automotive, chemical, electronics, and other demanding industries. Our comprehensive capabilities include mass production and custom fastener solutions, all manufactured with exceptional accuracy and efficiency. Trust TSM for competitive pricing, reliable supply, and premium quality aluminum fasteners that enhance your project performance.

What Are Aluminum Fasteners?

Aluminum fasteners are lightweight, durable mechanical components used to join or secure materials in industries ranging from aerospace to construction. Made from aluminum alloys like 6061 and 7075, these fasteners combine high strength-to-weight ratios, corrosion resistance, and thermal conductivity, making them ideal for applications requiring both performance and efficiency.

1. Bolts & Screws:

Hex bolts: For structural applications.

Self-tapping screws: Designed for aluminum-to-aluminum or mixed-material joints.

High-strength aerospace bolts: Made from 7075-T6 alloy for extreme load-bearing capacity.

2. Nuts & Washers:

Lock nuts: Prevent loosening under vibration.

Flange nuts: Integrated washers for distributed load.

3. Rivets:

Blind rivets: Ideal for hollow structures.

Solid rivets: Used in high-stress environments like aircraft assembly.

Applications of Aluminum Fasteners

✔Aerospace: 7075-T6 rivets for aircraft frames.

✔Automotive: 6061-T6 bolts for lightweight chassis.

✔Construction: Anodized anchors for corrosion-resistant structures.

✔Marine: Saltwater-resistant fasteners for shipbuilding.

Quality Control Tests for Aluminum Fasteners

Test Category | Test Item | Standard / Method |

Dimensional Inspection | Thread Verification | ISO 1502 (Go/No-Go) |

Tolerance Check | ISO 2768-m/f | |

Head/Drive Features | Digital measurement | |

Mechanical Properties | Tensile Strength | ASTM E8 |

Hardness Test | Brinell (HB) | |

Torque-to-Failure | Industry standard | |

Corrosion Resistance | Salt Spray Test | ASTM B117 |

Cyclic Exposure Test | Custom protocol | |

Surface Quality | Coating Thickness | Digital thickness gauge |

Adhesion Test | ISO 2409 (Cross-cut) | |

Visual Inspection | Magnification / Naked eye | |

Material Composition | Spectrometry Analysis | XRF / OES |

RoHS Compliance | Directive 2011/65/EU |

Applications

Aerospace: High-strength 7075 aluminum set screws are commonly used for clamping and positioning aircraft avionics equipment.

Electronics and Communications: 6061 screws are used for circuit board support, chassis fixing, and electromagnetic interference resistance.

Mechanical Equipment: Used for positioning and locking precision instruments and robotic joints.

Automotive: Lightweight positioning fasteners reduce vehicle weight and improve fuel economy.

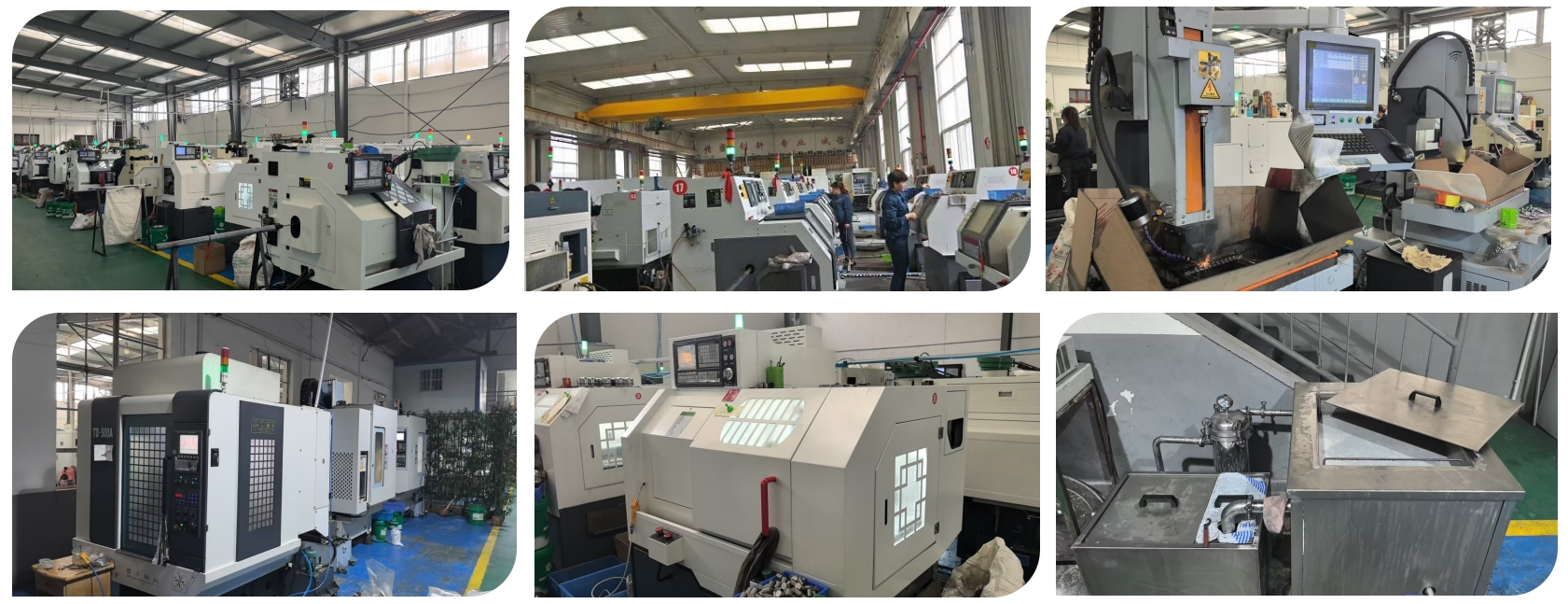

TSM factory and Processing equipment

FAQ

Q: How do 6061 and 7075 alloys differ in performance?

A: 7075 offers 2x higher tensile strength than 6061 but requires protective coatings for harsh environments.

Q: Are TSM’s fasteners compliant with international standards?

A: Yes, all products meet ASTM, DIN, and ISO specifications.

Q: What is the MOQ for bulk orders?

A: Minimum order starts at 1,000 units, with volume-based discounts.

Request a Quote Today!

Elevate your projects with TSM TECHNOLOGY’s aluminum fasteners. Contact us for: info@tsmfasteners.com